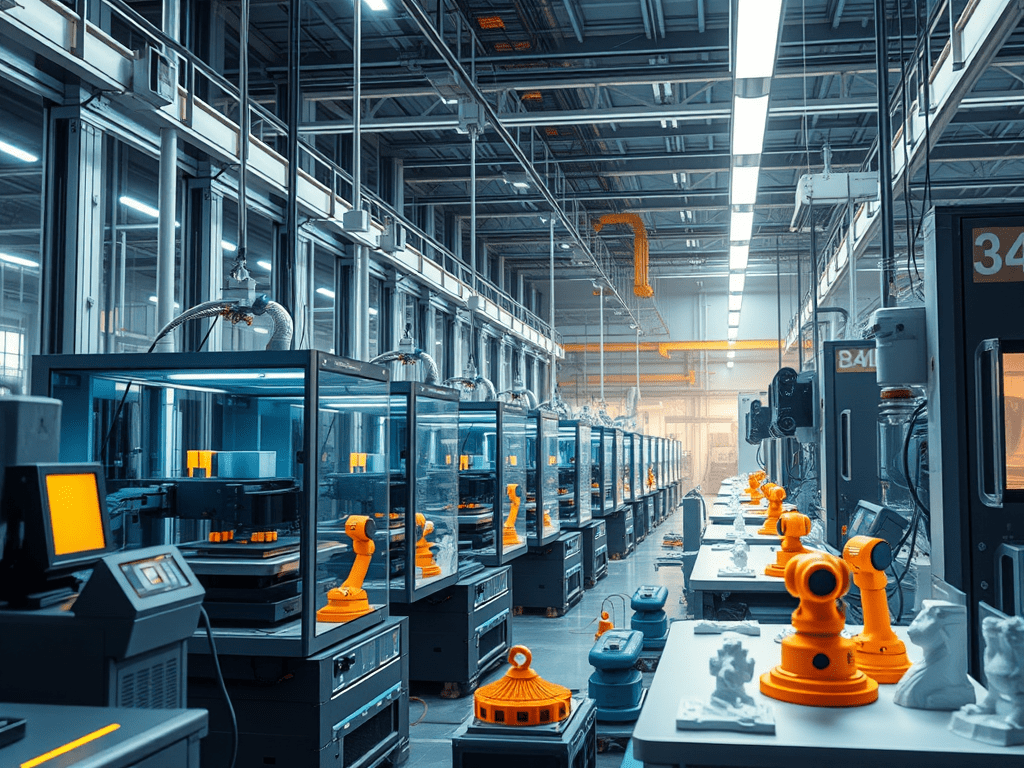

In today’s fast-moving world, speed, accuracy, and sustainability are more important than ever. Because of this, traditional manufacturing is changing in big ways. Digital manufacturing using tools like Artificial Intelligence (AI), 3D printing, and automation is leading the way into what’s known as Industry 4.0.

These advanced technologies aren’t just for giant factories or global companies anymore. Now, businesses of all sizes can use them to make smarter decisions, produce goods on demand, and offer more customized products. Whether it’s AI predicting when machines need repairs or 3D printers creating complex parts, this new way of manufacturing is changing how products are designed, built, and delivered.

In this blog, we’ll break down how digital manufacturing is transforming industries, boosting innovation, cutting waste, and paving the way for a smarter and more sustainable future. Whether you’re a business owner, engineer, investor, or just curious this is your guide to the future of manufacturing.

hinglish

Aaj ke fast-moving world mein, speed, accuracy aur sustainability bahut hi important ho chuki hai. Isi wajah se traditional manufacturing bhi ab tezi se badal rahi hai. Digital manufacturing jo ki Artificial Intelligence (AI), 3D printing, aur automation jaise tools ka use karti hai ab Industry 4.0 ka core ban gayi hai.

Ab ye advanced technologies sirf bade factories ya multinational companies tak simit nahi hain. Aaj har size ke business inka use karke smarter decisions le sakte hain, on-demand products bana sakte hain, aur customized solutions offer kar sakte hain. Chahe AI se machine ki breakdown pehle se predict karna ho ya 3D printers se complex parts banana ye naya manufacturing system pura process ko hi badal raha hai.

Is blog mein hum dekhenge kaise digital manufacturing industries ko transform kar rahi hai, innovation ko boost kar rahi hai, waste ko reduce kar rahi hai, aur ek smarter, more sustainable future create kar rahi hai. Chahe aap business owner ho, engineer, investor ya bas tech ke shaukeen ye blog aapko future manufacturing ki ek clear picture dega.

https://pagead2.googlesyndication.com/pagead/js/adsbygoogle.js?client=ca-pub-4610047145349526

What is Digital Manufacturing?

Digital Manufacturing refers to the application of digital technologies across the entire manufacturing lifecycle from product design to production, logistics, and maintenance.

It integrates CAD (Computer-Aided Design), CAM (Computer-Aided Manufacturing), data analytics, IoT, AI, and robotics into a unified system. This approach enhances visibility, speeds up innovation, and optimizes resource usage in real time.

Key Characteristics:

- Real-time data integration

- Smart machines and systems

- Digital twins of products or processes

- Cyber-physical connectivity

Artificial Intelligence in Manufacturing

AI is transforming how decisions are made on the factory floor.

1. Predictive Maintenance

AI algorithms process sensor data to predict equipment failure. This proactive approach minimizes unplanned downtime, reduces repair costs, and extends machinery life.

Example: Siemens uses AI to predict when its gas turbines need maintenance, saving millions annually.

2. Quality Control

Computer vision powered by AI can detect even microscopic flaws in products. This leads to fewer defective items, less waste, and better customer satisfaction.

3. Process Optimization

AI continuously learns from production data to identify bottlenecks, suggest improvements, and even auto-correct processes in real-time.

Result: Higher productivity, leaner operations, and lower costs.

3D Printing: Revolutionizing Production

3D printing, or Additive Manufacturing, is enabling a shift from mass production to mass customization.

Key Advantages:

- Rapid Prototyping: Designers can go from concept to prototype in hours.

- Tool-less Production: No need for costly molds or dies.

- Complex Geometry: Manufacture shapes that are impossible via traditional methods.

- Localized Manufacturing: Produce closer to the point of use, reducing logistics and emissions.

Case Study: GE’s fuel nozzles for jet engines are now 3D printed as a single part replacing 20 individual components. This reduced weight, improved performance, and simplified the supply chain.

Industries Benefiting from 3D Printing:

- Aerospace

- Medical (prosthetics, implants)

- Automotive

- Consumer Goods

- Construction (3D-printed homes)

Automation: The Rise of Smart Factories

Automation isn’t new but today, it’s intelligent, adaptive, and interconnected.

1. Robotics & Cobots

Modern robots are agile, safe, and can collaborate with humans. Cobots enhance worker capabilities rather than replace them.

2. IoT & Smart Sensors

Machines now come with embedded sensors that monitor performance, wear and tear, and environment transmitting data to central systems for decision-making.

3. Lights-Out Manufacturing

In some advanced facilities, entire production lines run 24/7 with no human intervention. This is possible through the convergence of AI, robotics, and machine learning.

Result: Consistent output, minimal human error, reduced operational costs.

Digital Manufacturing & Sustainability

The shift to digital also supports environmental goals.

- Energy Efficiency: AI optimizes power usage based on workload and demand.

- Material Savings: 3D printing uses only what’s needed zero excess.

- Circular Economy: Digital platforms help track, reclaim, and recycle materials more efficiently.

Emerging Trend: Integration of solar-powered factories and green automation systems with AI-enabled energy management.

Benefits At a Glance

| Feature | Benefit |

|---|---|

| AI-Driven Analytics | Faster decisions, reduced downtime |

| 3D Printing | Custom products, rapid prototyping |

| Robotics | High precision, low human error |

| IoT Sensors | Real-time monitoring |

| Automation | Round-the-clock production |

| Cloud Integration | Scalable, remote access |

| Digital Twins | Real-time simulation & optimization |

| Sustainability | Reduced waste and carbon footprint |

Industry Case Studies:

Siemens

Runs a fully digitized factory in Amberg, Germany. Over 1,200 products are manufactured daily with 99.9% accuracy, thanks to AI, IoT, and robotics.

Ford

Uses 3D printing to create tooling, saving time and cutting production costs by millions.

Adidas

Developed a “Speedfactory” in Germany using digital manufacturing to create customized shoes faster than ever before.

What’s Next? The Future of Digital Manufacturing

As innovation accelerates, the next frontier includes:

- Digital Twins for full-scale factory simulations

- Blockchain in supply chains for transparency and trust

- Edge Computing for real-time machine intelligence

- Human-AI collaboration platforms

- Decentralized micro-factories for localized production

- Integration of AR/VR for remote factory monitoring and training

Final Thoughts: Embrace or Be Left Behind

Digital manufacturing is not a trend it’s a transformation. Companies that adopt AI, 3D printing, and automation will lead the next industrial revolution. Those that don’t struggle to survive in a landscape driven by speed, customization, and data.

The question isn’t “if” your business should go digital it’s “how fast” you can do it.

Actionable Steps for Businesses

- Start with pilot projects using AI or automation in non-critical areas.

- Upskill your workforce in digital tools and analytics.

- Invest in cloud-based manufacturing platforms.

- Collaborate with startups or tech partners.

- Measure ROI continuously to scale successfully.

Conclusion: The Future is Being Built Today

Digital manufacturing isn’t a distant vision it’s already here, reshaping how industries think, build, and grow. With AI optimizing operations, 3D printing enabling on-demand customization, and automation improving speed and accuracy, businesses can now be more efficient, flexible, and sustainable than ever before.

Whether you’re a startup exploring rapid prototyping, a large-scale manufacturer streamlining supply chains, or an investor tracking emerging trends, digital manufacturing offers countless opportunities. Embracing these technologies is no longer optional it’s essential to stay competitive in a rapidly changing world.

As we move deeper into the Industry 4.0 era, the companies that thrive will be those that combine digital intelligence with bold innovation. The tools are ready. The transformation has begun. The question is are you ready to build the future?

Leave a comment