Discover why legal and medical businesses remain the most future-proof industries. From HealthTech to LegalTech, explore opportunities in healthcare, law, compliance, and innovation that make these sectors safe bets for entrepreneurs and investors.

Why Legal and Medical Businesses Are the Safest Bets for the Future Economy

In today’s fast changing world, businesses rise and fall at lightning speed. Startups are born overnight, industries get disrupted by technology, and consumer preferences evolve faster than ever before. But amid this uncertainty, some sectors stand tall resilient to economic downturns and always in demand. Two of these evergreen industries are the medical and legal businesses.

Both sectors are not only essential to human society but also entering a phase of massive transformation fueled by technology, innovation, and global market needs. For entrepreneurs and investors searching for future-proof opportunities, healthcare and legal services remain the safest long-term bets.

Hinglish

Aaj ke fast changing world mein businesses lightning speed se rise aur fall ho rahe hain. Startups ek raat mein born ho jaate hain, industries technology se disrupt hoti hain, aur consumer preferences bhi bahut jaldi evolve karte hain. Lekin is uncertainty ke beech kuch sectors aise hain jo hamesha strong khade rehte hain economic downturns se resilient aur hamesha demand mein. Unhi evergreen industries mein se do sabse important hain: Medical aur Legal businesses.

Dono sectors sirf human society ke liye essential hi nahi, balki ab ek naye transformation phase mein enter kar rahe hain technology, innovation aur global market needs ke saath. Entrepreneurs aur investors ke liye jo log future proof opportunities dhundh rahe hain, unke liye healthcare aur legal services sabse safe long-term bets hain.

The Medical Business: Healthcare in Transformation

Health is not optional it’s a necessity. This makes the medical business one of the most recession proof industries in existence. No matter the economy, people will always need doctors, medicines, and healthcare support. But what’s changing is how medical services are delivered and consumed.

🔹 Growing Demand

- Aging populations: By 2050, one in six people globally will be over 65, creating unprecedented demand for medical care.

- Lifestyle diseases: Conditions like diabetes, heart disease, and obesity are on the rise, especially in developing countries.

- Health awareness: Post-COVID, people are investing more in preventive and wellness care.

🔹 Emerging Opportunities in Healthcare

- Telemedicine & Virtual Care – Patients can now consult doctors via apps, reducing costs and improving access.

- Mental Health Startups – Counseling, therapy platforms, and mindfulness apps are seeing huge adoption.

- Preventive Health, Fitness & Nutrition – From wearables to personalized diet plans, the wellness economy is booming.

- Biotech & Personalized Medicine – Tailor-made treatments based on genetics are unlocking billion-dollar opportunities.

- Affordable Rural Healthcare – In India and other emerging markets, Tier-2/Tier-3 cities offer untapped potential.

🔹 Why It’s Recession-Proof

Healthcare is essential when people fall sick, they don’t postpone treatment. Even in economic slowdowns, the medical sector remains steady, making it a safe, long-term business bet.

The Legal Business: Complexity Creates Opportunity

As the economy grows more complex, so do the legal needs of businesses and individuals. Every new technology, regulation, or cross-border deal brings new legal challenges—and lawyers are essential to solving them.

🔹 Why Demand is Rising

- Startups and corporate need fundraising, contracts, and IP protection.

- The digital economy brings cybersecurity, AI regulation, and data privacy laws.

- Global trade requires cross-border compliance and tax expertise.

- Everyday citizens need help with property, family disputes, and litigation.

🔹 Emerging Opportunities in Legal Sector

- Startup & Corporate Law – Supporting fundraising, acquisitions, and intellectual property rights.

- Cyber Law & AI Regulations – As AI tools boom, compliance around ethics and privacy will grow.

- Data Protection & Privacy Compliance – New laws like GDPR and India’s DPDP Act create consulting demand.

- Online Dispute Resolution – Virtual courts and arbitration platforms will become mainstream.

- LegalTech Startups – AI-driven contract review, automated compliance tools, and legal research platforms are growing fast.

🔹 Why It’s Recession-Proof

Legal services are not optional for businesses regardless of the economy, companies must remain compliant and individuals will always face disputes that require resolution. This makes legal businesses consistent and resilient.

Where Legal Meets Medical

The line between healthcare and law is getting thinner every year. As medical businesses adopt advanced technologies and expand across borders, legal frameworks are playing a critical role in ensuring patient safety, compliance, and ethical practices. This overlap is creating a fast-growing niche industry: medical law and healthcare compliance.

🔹 1. Data Privacy & Patient Confidentiality

Healthcare today generates enormous amounts of sensitive data—electronic health records, genetic information, insurance details, and more. This data is highly valuable but also vulnerable.

- Regulations in place: HIPAA in the U.S., GDPR in Europe, and India’s DPDP Act.

- Opportunity: Hospitals, clinics, and digital health startups need legal consultants and compliance officers to navigate these laws.

- Future trend: As AI diagnostic tools and wearable devices collect more personal health data, demand for legal-medical advisory services will skyrocket.

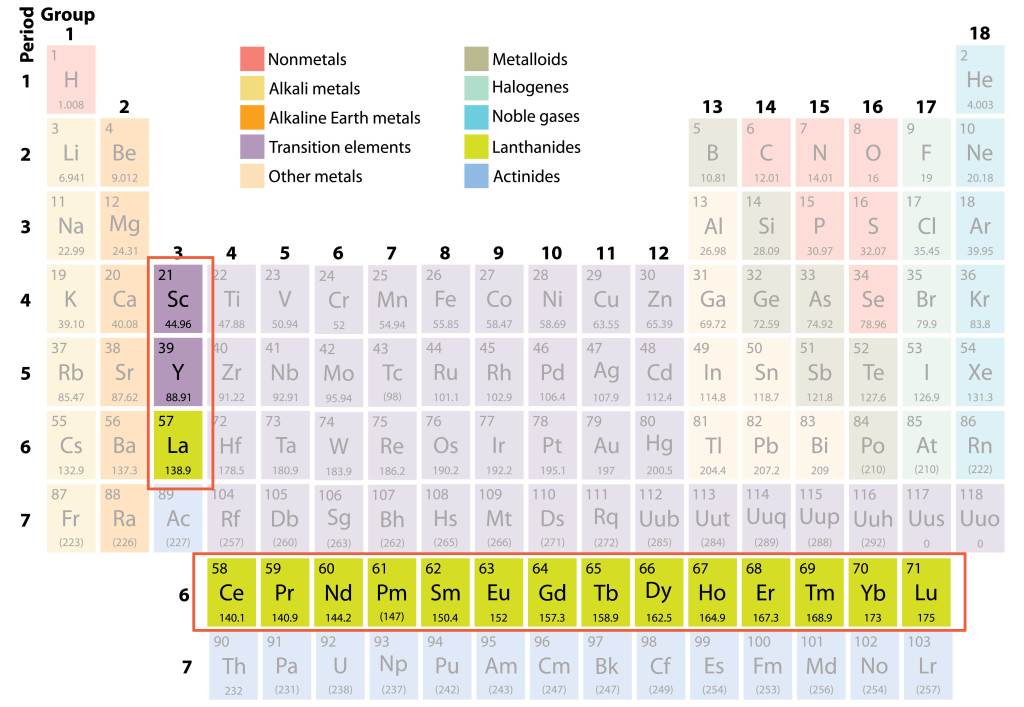

🔹 2. Biotech, Pharma, and Clinical Trials

The pharmaceutical and biotechnology industries are highly regulated because they directly impact human lives.

- Regulations in place: FDA approvals (U.S.), EMA (Europe), and CDSCO (India).

- Key legal needs:

- Patent protection for new drugs and biotech innovations.

- Legal guidance on clinical trial protocols and patient consent.

- Navigating international drug approval processes.

- Opportunity: Startups working in genetic research, stem cells, or personalized medicine will need specialized legal advisors.

🔹 3. Medical Malpractice & Patient Rights

With greater awareness, patients are more willing to challenge hospitals and doctors legally.

- Growing demand: Litigation around surgical errors, wrong diagnoses, negligence, or insurance disputes.

- Legal-business opportunity: Law firms specializing in medical negligence and patient rights cases are thriving worldwide.

- Healthcare-business opportunity: Hospitals need in-house legal teams to handle disputes and protect reputations.

🔹 4. Telemedicine & Digital Health Regulations

Telemedicine has exploded since COVID-19, but legal frameworks are still catching up.

- Challenges:

- Licensing issues (can a doctor in India consult a patient in other part of world ?).

- Cross-border insurance coverage.

- Validity of prescriptions issued via video consultations.

- Opportunity: HealthTech startups offering Telemedicine platforms need continuous legal oversight for global operations.

🔹 5. Insurance & Compliance

The medical industry is tightly linked with insurance, and this creates complex legal challenges.

- Example: Denial of claims, fraudulent insurance practices, or disputes over coverage.

- Business potential: Legal services that focus on health insurance claims, settlements, and compliance.

🔹 6. The Rise of Legal-Medical Advisory Firms

In the near future, we’ll see more specialized firms that combine legal and medical expertise.

These firms will serve as bridges between doctors, patients, regulators, and businesses.irms, a niche with massive future potential.

Services they can offer:

- Compliance audits for hospitals & HealthTech startups.

- Legal frameworks for clinical trials and biotech research.

- Patient rights consulting and insurance dispute management.

These firms will serve as bridges between doctors, patients, regulators, and businesses.

Future Outlook: Opportunities for Entrepreneurs & Investors

For anyone looking to start or invest in a future proof business, medical and legal sectors offer unmatched stability and growth.

- Healthcare Tech (HealthTech) is one of the fastest-growing startup segments, expected to cross $660 billion globally by 2025.

- LegalTech is expanding too, projected to reach $45 billion globally by 2030 as AI and automation take center stage.

- Investors are actively funding startups that combine AI, compliance, and service delivery in both industries.

For entrepreneurs, the key lies in adopting technology whether that’s building a Telemedicine app, launching a legal automation tool, or creating niche consulting services that combine both fields.

Conclusion

While trends come and go, two industries will never lose relevance healthcare and law. As the world becomes more digital, interconnected, and complex, the demand for doctors to heal and lawyers to protect will only grow stronger.

For entrepreneurs, startups, and investors, the medical and legal businesses stand out as the safest and smartest bets for the future economy not just because they are recession-proof, but because they are evolving with technology in exciting new ways.

If you’re looking to build or back the next big thing, start where the demand is eternal: health and law.

Hinglish

Trends aate hain aur chale jaate hain, lekin do industries aisi hain jo kabhi apni relevance lose nahi karegi Healthcare aur Law. Jaise jaise duniya zyada digital, interconnected aur complex hoti ja rahi hai, waise-waise demand doctors ki (jo heal kare) aur lawyers ki (jo protect kare) aur bhi strong hoti jaayegi.

Entrepreneurs, startups aur investors ke liye, medical aur legal businesses future economy ke liye safest aur smartest bets hain sirf isliye nahi ki yeh recession proof hain, balki isliye bhi ki yeh technology ke saath evolve ho rahi hain aur naye exciting opportunities create kar rahi hain.

Agar aap next big thing build karna chahte ho ya usme invest karna chahte ho, toh shuru karo waha se jahan demand hamesha rahegi: Health aur Law.